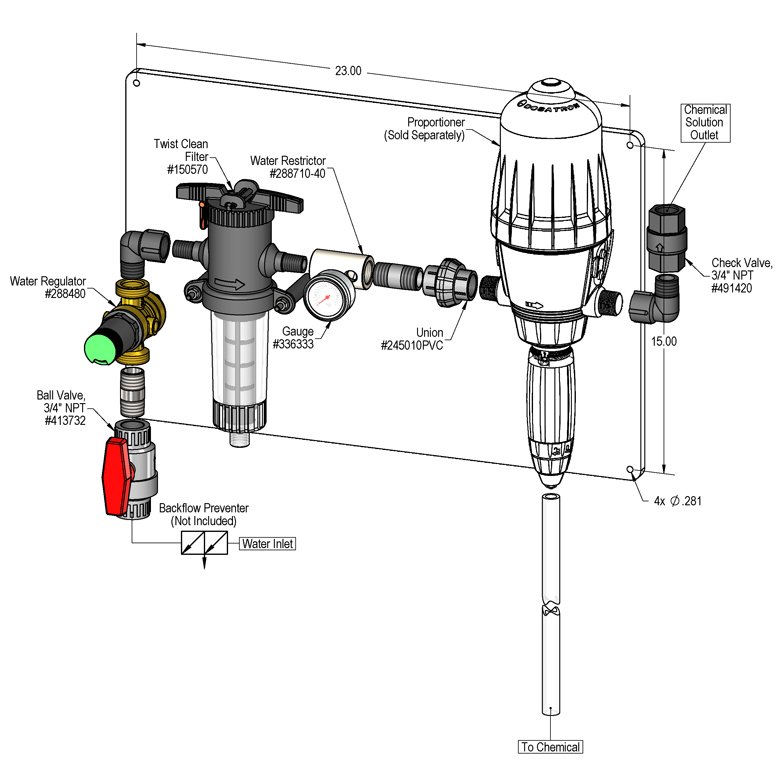

| Water | |

| Temperature | up to 104°F |

| Pressure | 5-85 PSI |

| Flow | up to 14 GPM |

| Supply Line | 3/4'' |

Lafferty Equipment Manufacturing, LLC

Installation & Operation Instructions

Model # 909900 · Single Dosing Panel (Injector NOT Included)

Requirements

Overview

Water powered proportioners are water-driven, non-electrical, proportional dispensing systems that dilute chemical concentrates to required ratios and deliver RTU chemical solution to pump fed applicators. For convenience and ease of installation, the Single Dosing Panel features a polypropylene mounting plate and includes a water filter, water regulator, flow restrictor, pressure gauge, and a mounting bracket for an injector (available separately). Fully adjustable proportioners cover dilution ratios from 1:3000 up to 1:5 and a choice of Viton, Aflas or Kalrez seals are available for chemical compatibility.