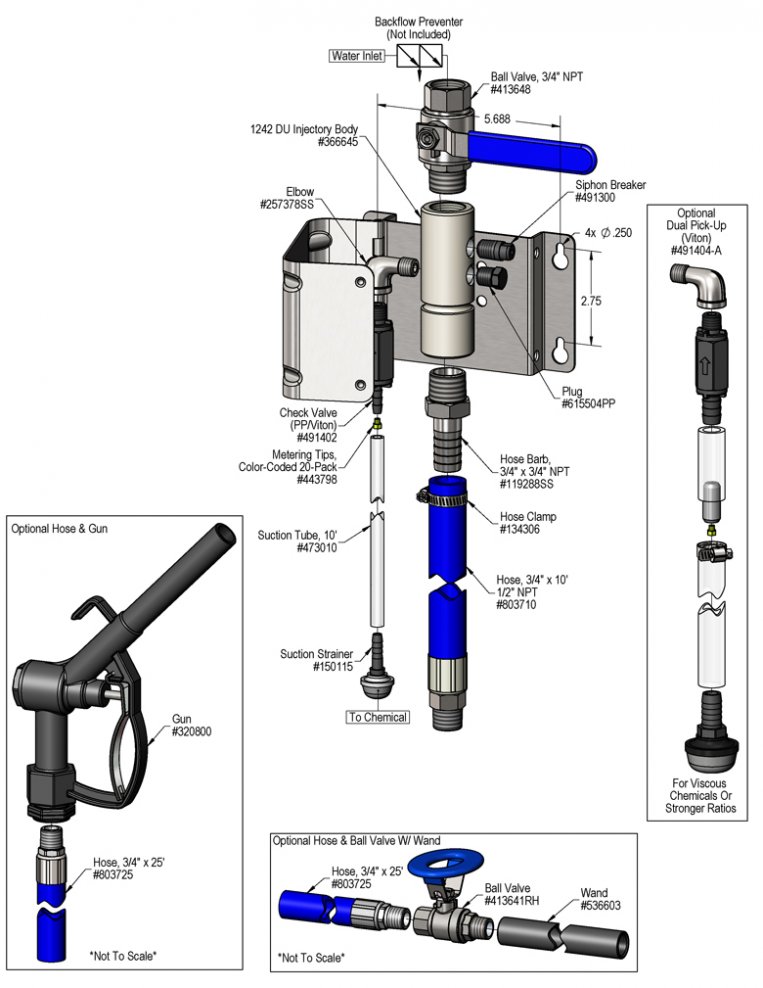

Set the chemical dilution ratio by threading one of the color coded metering tips into chemical check valve. See chemical label for dilution ratio recommendation or consult your chemical supplier.

- For the strongest dilution ratio do NOT install a colored metering tip. See note*

- The dilution ratios in the metering tip chart are based on water thin chemicals with a viscosity of 1CPS.

- Thicker chemicals will require a larger tip than the ratios shown in the chart.

- Select and thread the tip color that is closest to your desired chemical strength into the tip holder as a starting place. DO NOT OVER-TIGHTEN.

- Application results will ultimately determine final tip color.

- Push the chemical tubes over the check valves and place the strainer in the chemical concentrate.

- Push the discharge hose completely over the barb.

* For stronger no tip concentration to be achieved order and install the optional dual pick up kit. See chart.

- Remove the plug and siphon breaker, install kit, and replace siphon breaker.

- In the ratio chart, the dual pick up column shows ratios assuming that the standard suction tube has NO metering tip installed.

*This will also allow 2 different chemicals to be blended. Mix and match metering tips in the standard and optional second pick up assemblies to obtain ratios that are not possible using a single tip.