Overview

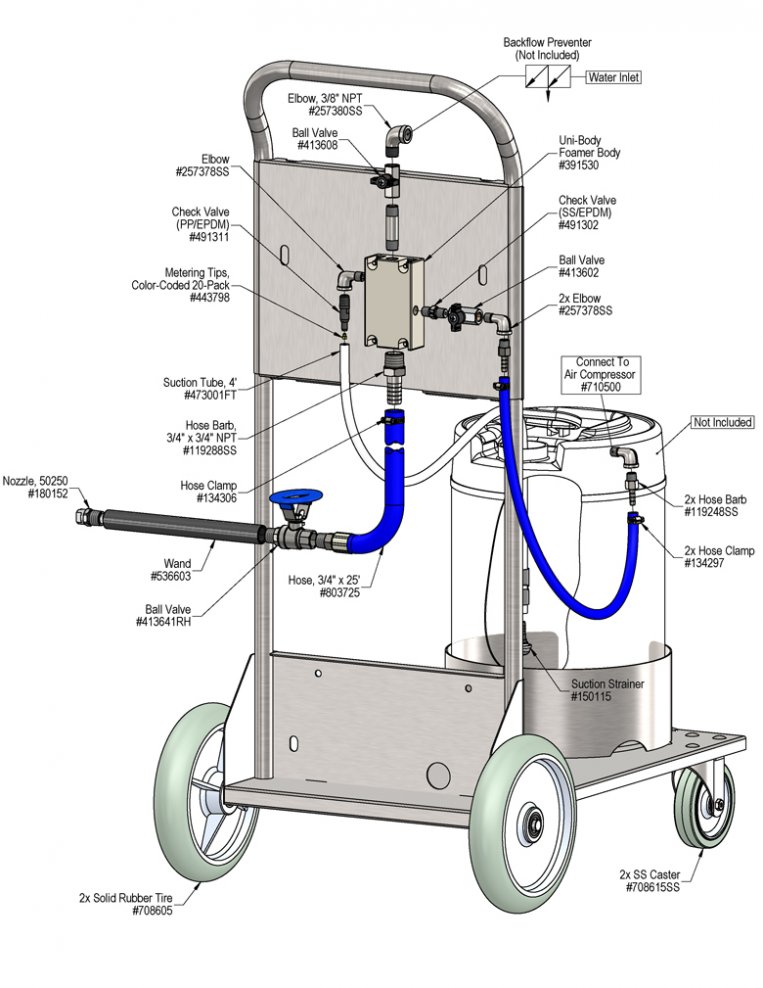

The Portable 5 Gallon Uni-Body LC Foamer is a medium volume foam applicator featuring an all stainless steel cart assembly and integrated 120V air compressor with GFI protection. It will project foaming chemicals on to any surface up close or at distances up to 12 feet. This venturi injection system uses standard city water pressure (35 - 125 PSI) to draw and blend chemical concentrate into the water stream to create an accurately diluted solution. Rich, clinging foam is created by injecting compressed air into the solution to greatly increase volume and coverage ability. The foam is then projected through the discharge hose and fan nozzle.