Overview

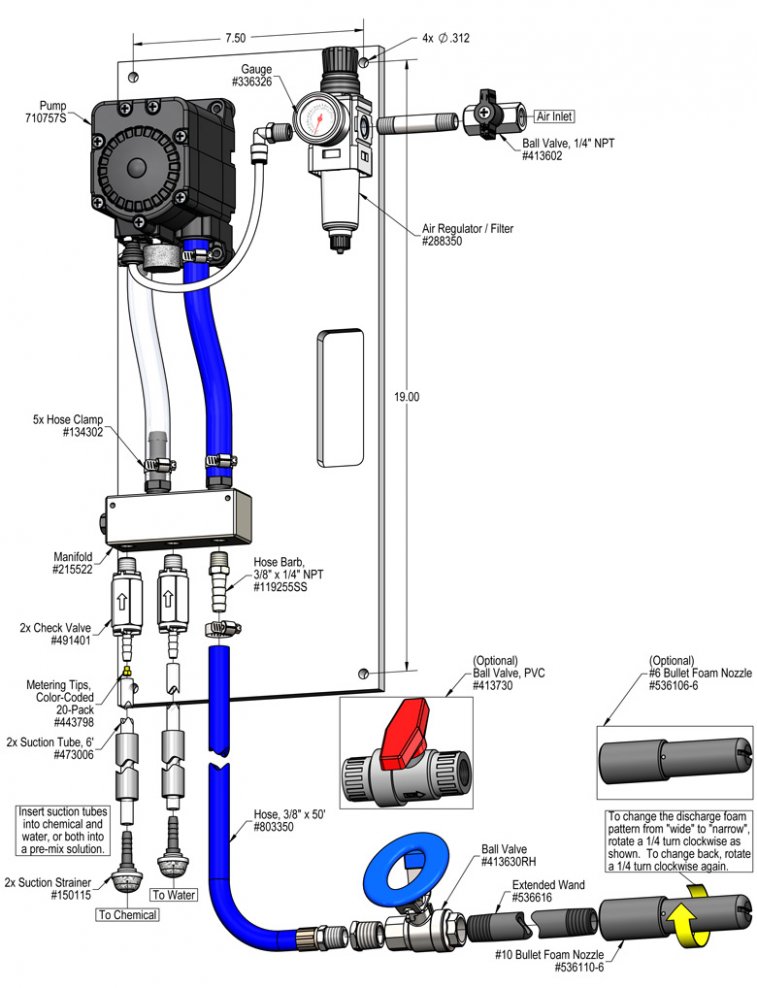

The Bullet™ Foamer is a low volume foam applicator that is ideal for applying foaming chemicals to close-up surfaces and hard to reach areas. A Flojet air-operated, double-diaphragm pump draws ready-to-use chemical from one static tank or blends water and chemical concentrate from two static tanks to create a wide range of dilution ratios. The solution is then projected through the discharge hose, extended wand and Bullet™ nozzle which draws in atmospheric air to create wet, clinging foam. This unique nozzle can be adjusted to project a wide or narrow foam pattern.