Overview

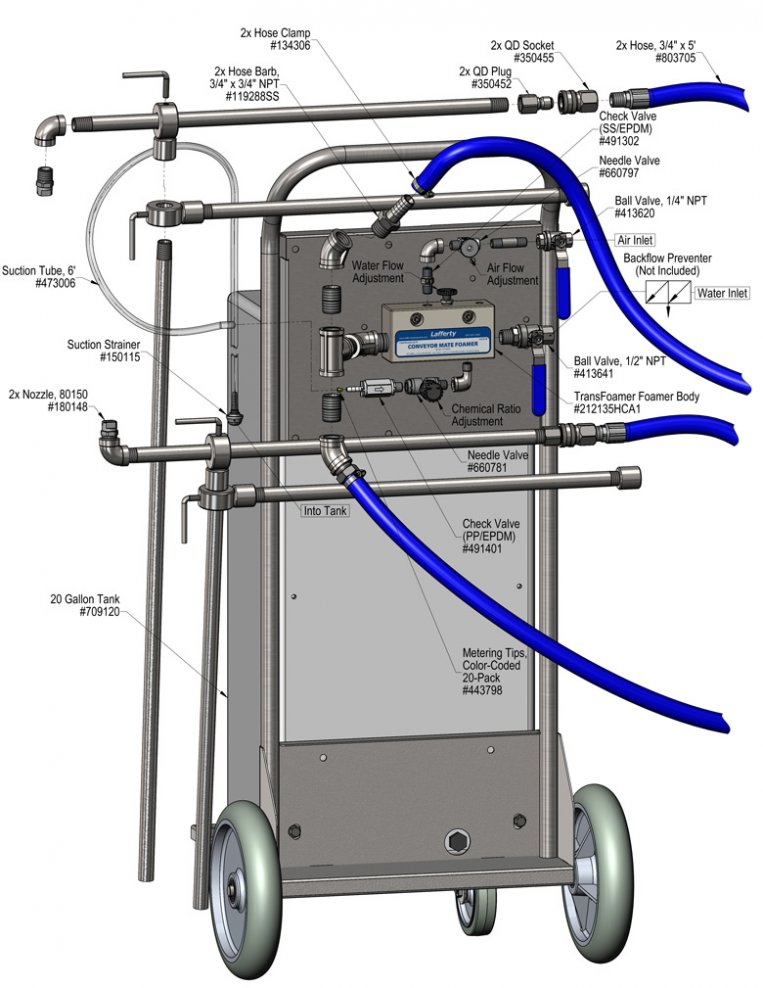

The Conveyor Mate is an adjustable foam applicator for Clean-In-Place foam application onto conveyor belts and other equipment. Featuring an all stainless steel cart assembly, this venturi injection system uses city or boosted water pressure (35 - 250 PSI) to draw and blend chemical concentrate from the attached tank into the water stream to create an accurately diluted solution. Rich, clinging foam is created by injecting compressed air into the foaming solution to greatly expand volume and coverage ability. This foamer can be set to achieve the desired foaming consistency and cleaning results by adjusting the chemical, water and air flow. The adjustable length/height extension arms allow the unit to foam conveyor belts up to 4 feet wide.