Overview

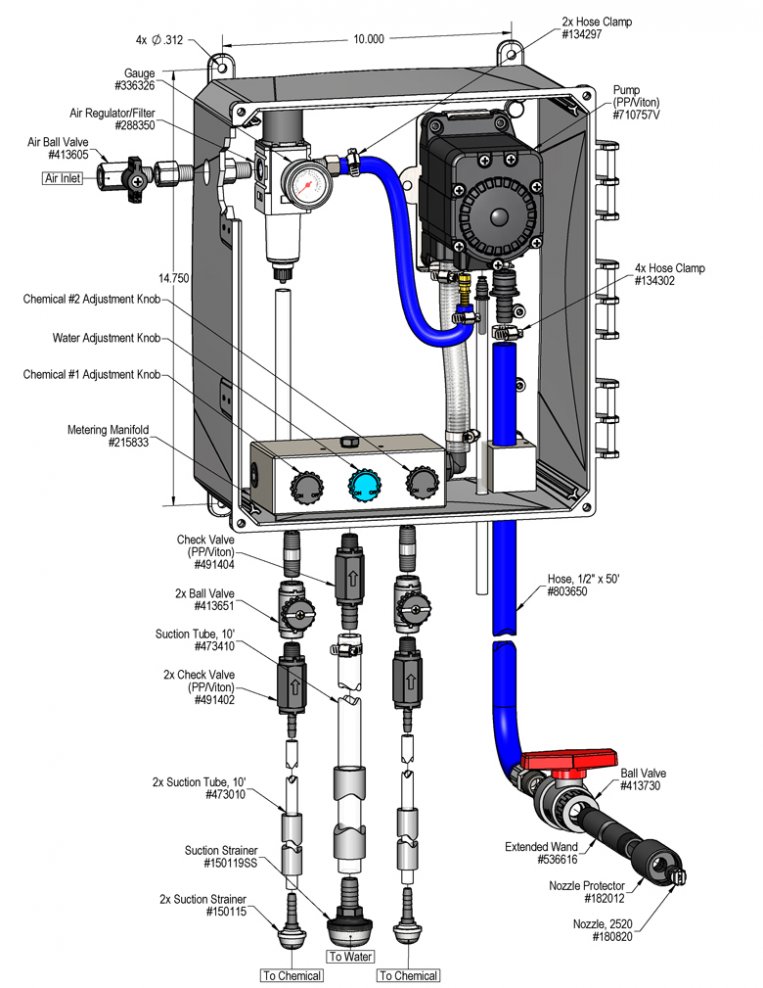

The 2-Way APV MM Concrete Sprayer is a spray applicator for projecting 2 highly corrosive chemicals such as those used to remove concrete and for aluminum brightening. It is designed for facilities with low or no water pressure. This acid-resistant system uses an air-operated, double-diaphragm, Flojet pump to draw water and chemical concentrate from separate static tanks and blend them to create a wide range of dilution ratios. A uniform spray is then projected through the hose, wand and fan nozzle on to any surface. Alternate between 2 different concentrations or chemicals using ball valves.