Overview

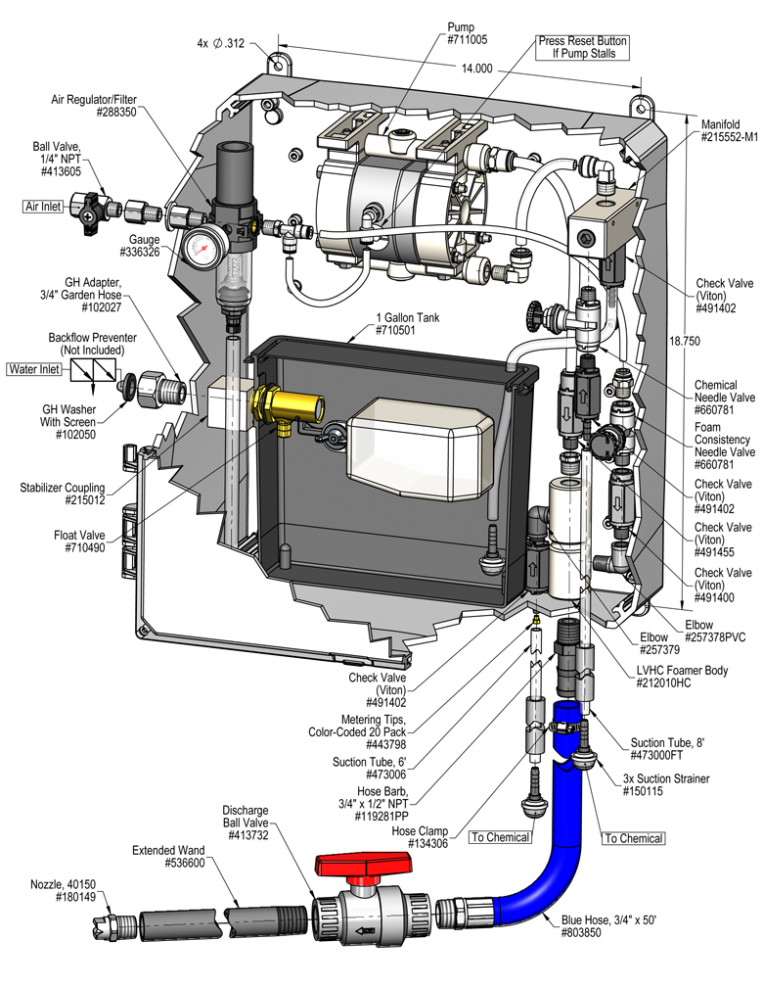

The 1-Way YPT-LV Concrete Foamer is a foam applicator for projecting highly corrosive chemicals such as those used to remove concrete and for aluminum brightening. This acid-resistant system uses a rugged 1/4" Yamada air-operated, double-diaphragm pump to pump water and drive the venturi LVHC foamer which draws chemical concentrate through precision metering tips to create dilution ratios of 2.5:1 (or weaker) with no chemical passing through the air pump. If a stronger ratio is required, this system includes an extra chemical pickup on the suction side of the pump for up to a 1:1 ratio. Compressed air is injected into the solution to create rich, clinging foam which is then projected through the foam hose, wand and fan nozzle.