Overview

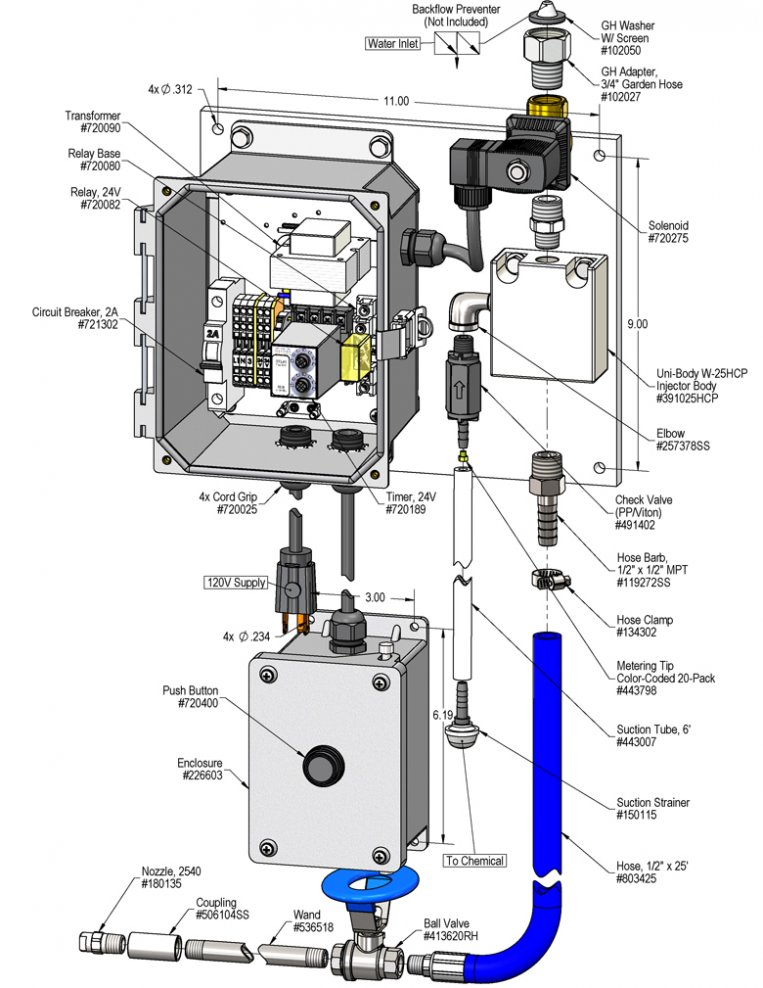

The Timed Asphalt Release Spray-All is a water-driven, time-delayed spray applicator for applying asphalt release chemicals on to truck beds or tools to prevent asphalt from sticking. This venturi injection system uses standard city water pressure (35 - 125 PSI) to draw and blend chemical concentrate into the water stream. Precision metering tips are used to create an accurately diluted solution which is projected through the discharge hose and fan nozzle as a uniform spray. With a flow rate of around 1.3 GPM @ 40 PSI, this unit is great for spraying down any sized vehicle or equipment quickly and efficiently. This unit features an adjustable dual-function timer which controls the length of application and the delay time which keeps the driver from immediately restarting the system, preventing costly over-application.