Overview

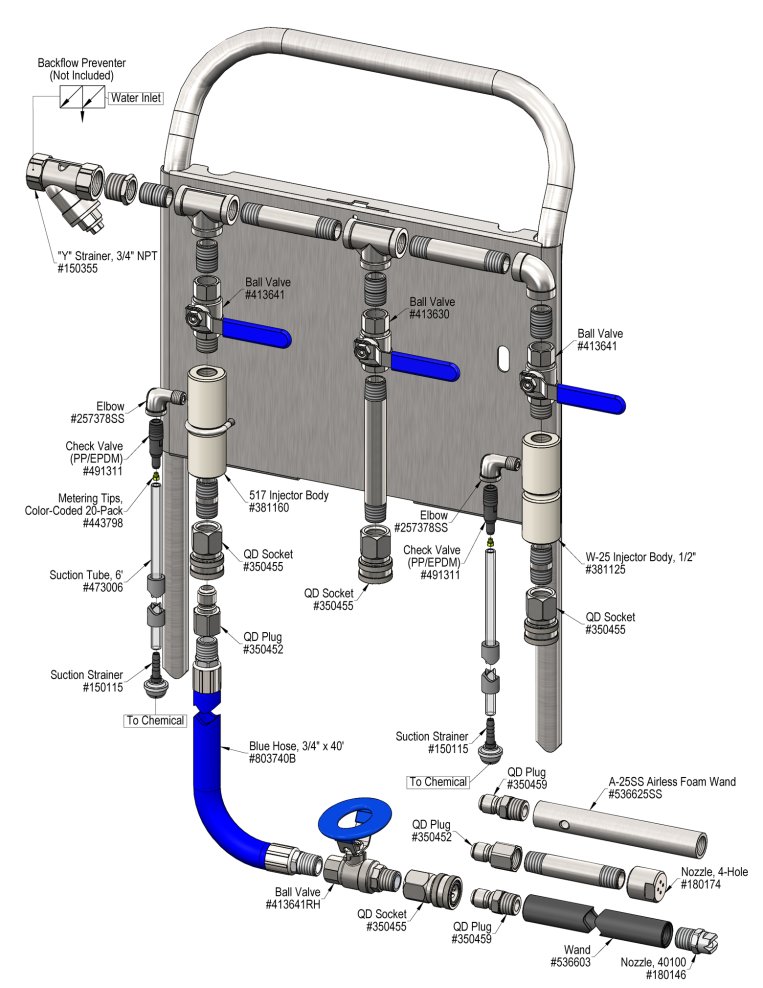

The Portable 517 Sanitize/Rinse/A-25 Airless Foam Hose Drop Station is a combination applicator for applying one chemical as wet airless foam, applying another as a high-volume sanitizing spray, and for rinsing (no compressed air required). Featuring an all stainless steel cart assembly, this venturi injection system uses standard city water pressure (35 - 125 PSI) to draw and blend chemical concentrates into the water streams to create accurately diluted solutions using precision metering tips to control chemical usage. The airless foam wand creates and projects wet, clinging foam at distances up to 6 feet. The sanitizer solution is projected as a "flooding" spray for fast complete coverage. Rinse at full pressure using a unique, powerful 4-hole nozzle.