| Ready-to-Use Chemical Solution | |

| Solution Temperature | 120°F MAX |

| Electric | 120V - Min.15 AMP Circuit |

Lafferty Equipment Manufacturing, LLC

Installation & Operation Instructions

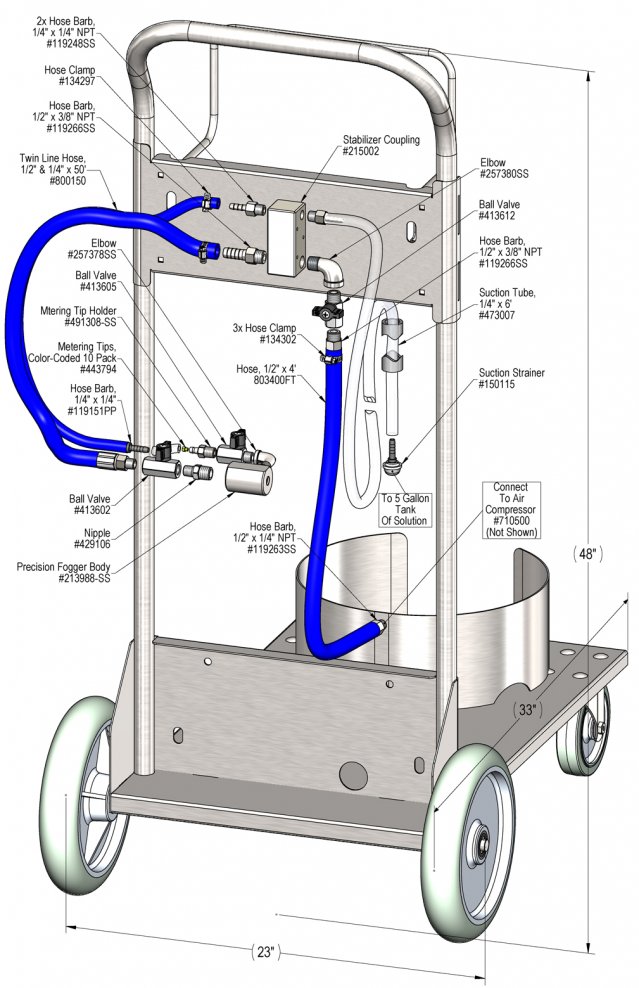

Model # 950730 · Portable Precision Fogger

Requirements

Overview

The Portable Precision Fogger is a damp mist sprayer that uses compressed air and venturi action to draw pre-diluted chemical solution from a user-supplied pail on the stainless steel cart. The chemical solution flows through the twin-line hose and thumb-gun to the fogger body, which atomizes the chemical and projects it up to 15 feet. The adjustable output can wet surfaces at close range or spray mist (fog) into the air to cover exposed surfaces and penetrate hard-to-reach areas. This unit features an on-board 120V air compressor and requires only an electrical connection. Used for disinfection, sanitizing, insecticide application, odor control, humidification and many other applications.