Overview

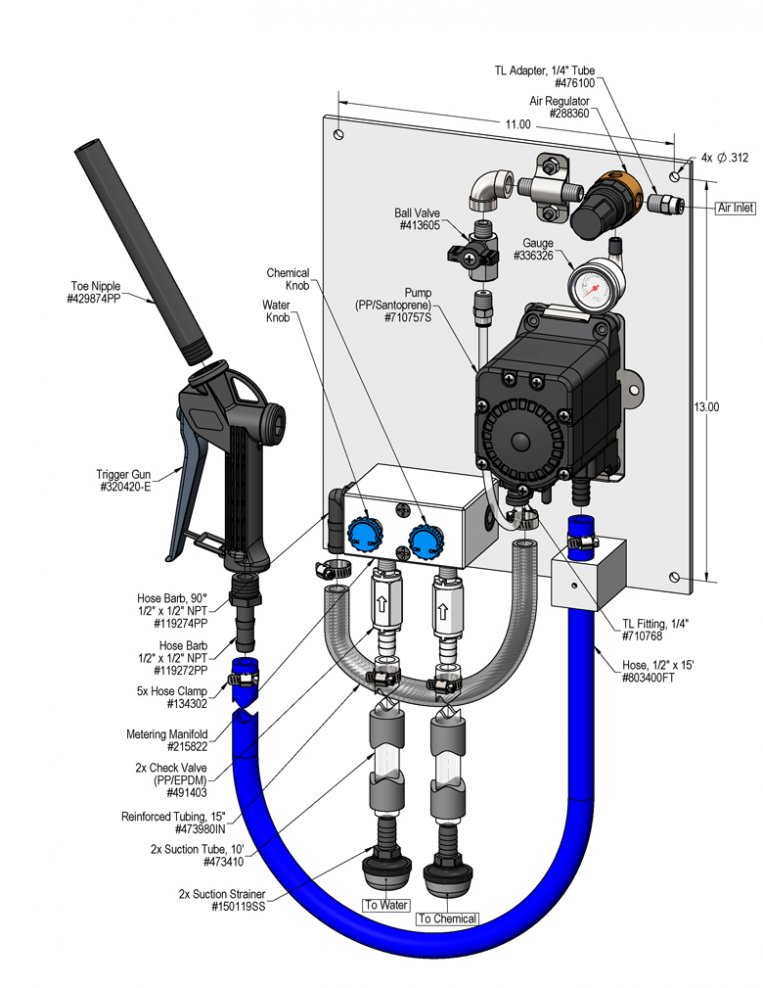

The 1-Way FPS MM Transfer System is a air pump driven chemical transfer system designed to blend 2 compatible chemical concentrates, or 1 chemical concentrate with water, and dispense the solution into any sized container. This unit uses a FloJet air pump to draw the 2 liquids through a unique metering manifold to create virtually any ratio. The solution is then dispensed into any container through a 15 foot discharge hose and trigger gun.