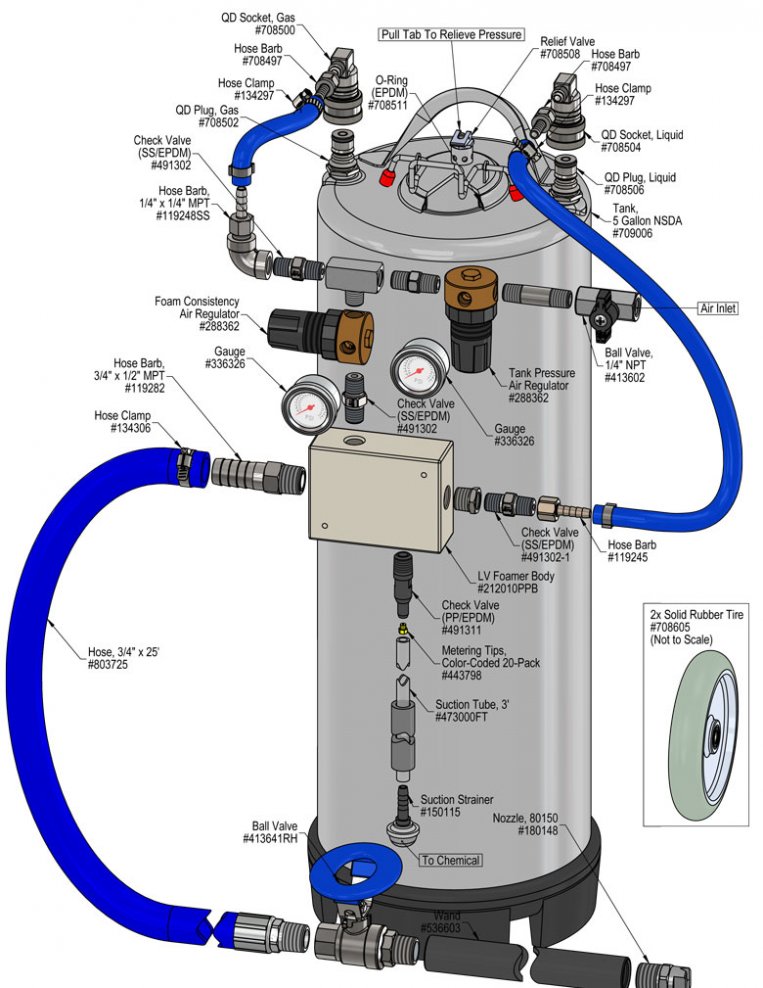

Overview

The 5 Gallon LV Tank Foamer is a low-volume venturi foam applicator that uses compressed air to pressurize the water in the tank to create the water pressure to draw and blend chemical concentrate into the water stream. Compressed air is injected into the solution which is projected as a low-volume of rich, clinging foam on to any surface up close or at distances up to 9 feet. Each fill provides 7 minutes of continuous foaming.