Overview

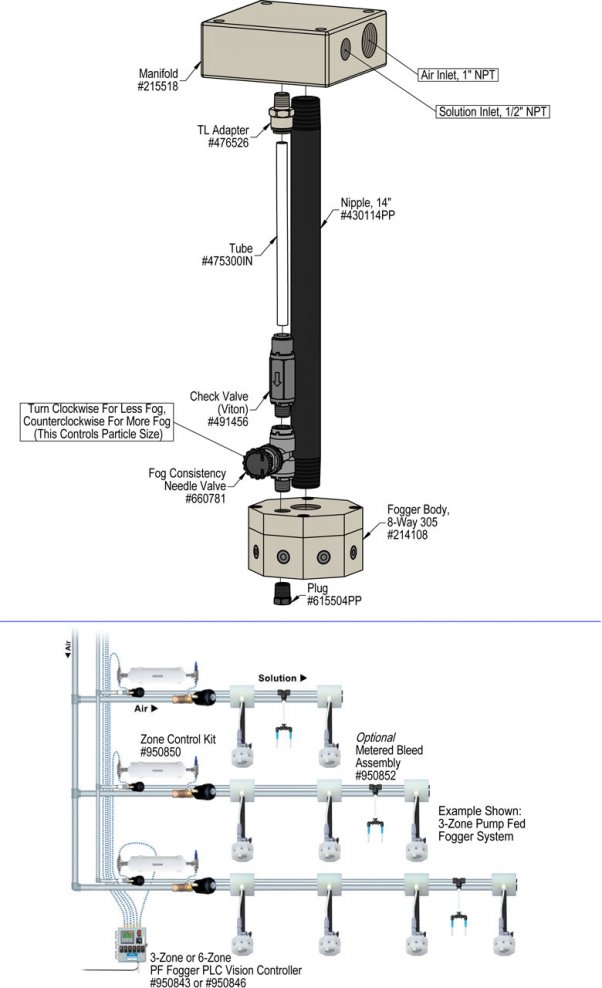

The 305 8-Way Pump Fed Fogger is a damp mist sprayer that receives ready-to-use chemical solution from a central pump system and uses compressed air (59 CFM @ 80 PSI) to project it up to 25 feet in 8 directions. The adjustable output sprays mist (fog) into the air to cover exposed surfaces and penetrate hard-to-reach areas.