Overview

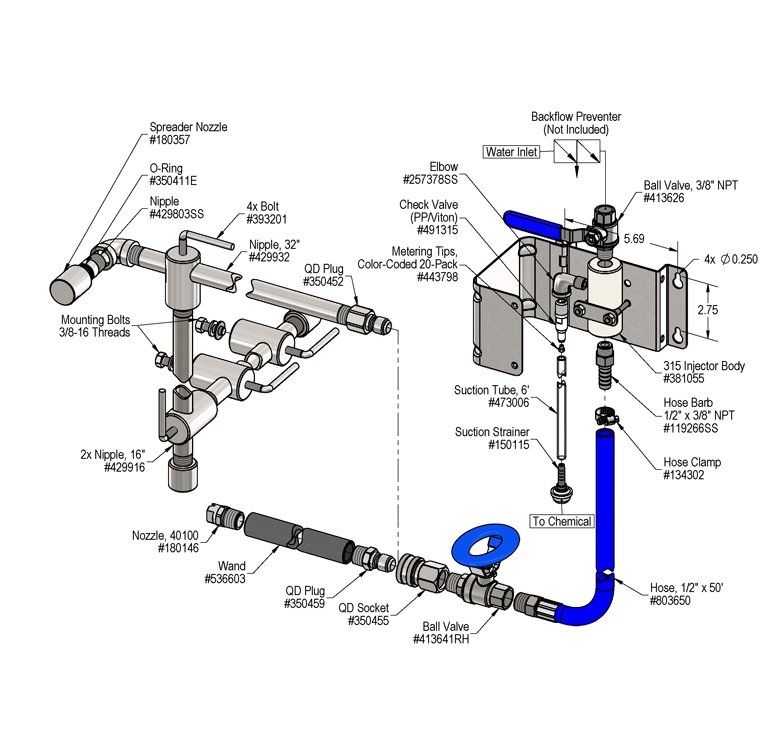

The Conveyor-Mate™ 315 Sanitizer System is specialized for Clean-In-Place spray sanitizing of conveyor belts and also can be used as a manual sanitizer. The stainless steel spray arm and nozzle assembly can be permanently or temporarily mounted to the conveyor belt housing or nearby surface. The fully adjustable spray arm extends vertically and horizontally to virtually any position. The unique stainless steel Spreader Nozzle™ creates a wide spray pattern that can be adjusted and rotated to ensure optimal coverage at any angle. The included 315 Sanitizer is a venturi dilution system that uses city water pressure (35 - 125 PSI) to accurately draw and blend chemical concentrate into the water stream. The solution is then projected through the discharge hose to the spray arm. Quick disconnect the spray arm and attach a wand for manual sanitizing.