| Electric | 120V |

| Entryway Foam Sanitizer | 976250, 976256, or 976260 |

Lafferty Equipment Manufacturing, LLC

Installation & Operation Instructions

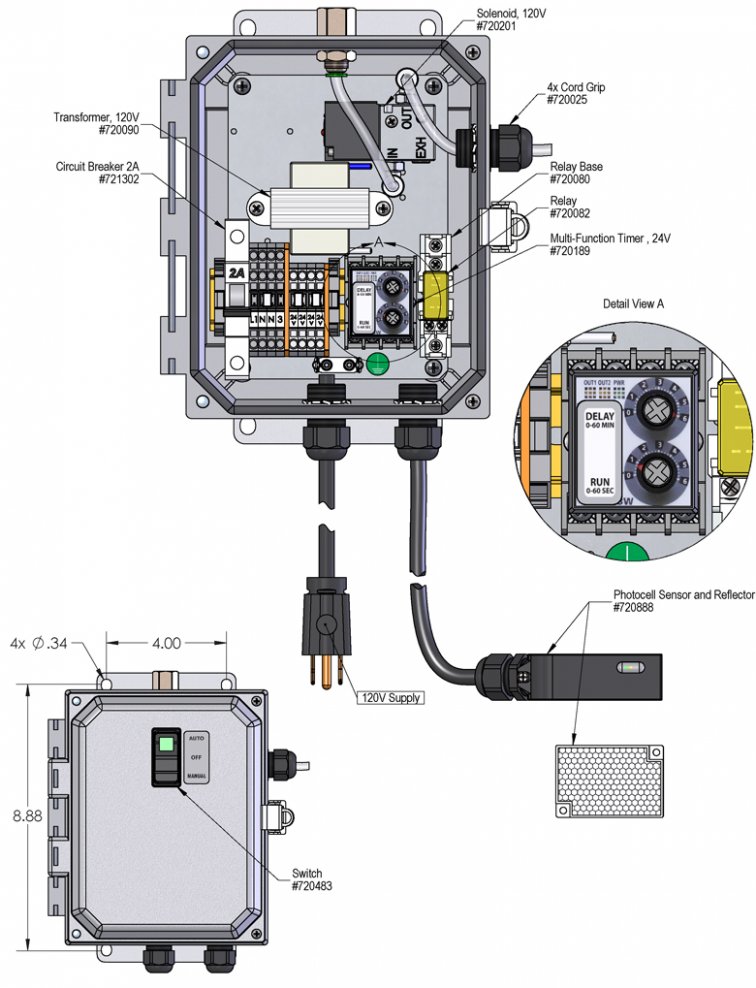

Model # 976003EE · Photocell Upgrade for Pump Fed Entryway Foam Sanitizers (Specify at Time of Purchase)

Requirements

Overview

The Photocell Upgrade allows any Pump Fed Timed Entryway Foam Sanitizer to be activated "on-demand" via a photocell sensor and apply foam to the entryway floor for a set amount of time. The multi-function timer also controls the minimum amount of time between activation, preventing costly over-application when traffic is heavy. Timer settings are field adjustable. This upgrade must be specified at the time of purchase.