Cleaning and sanitation is a critical part of the brewing process whether you’re a hobbyist, local Brewmaster, or the sanitation manager of a large beverage processing facility.

Welcome to the Lafferty Learning Center

Discover new products and learn how to select, install, operate, and maintain chemical application equipment. The Lafferty Learning Center presents decades of institutional knowledge, tips/tricks, and best practices in a visual multimedia format.

Product specific guidelines are provided in the Installation and Operation Instructions for each unit, which are available on the main Lafferty website.

Post Archive

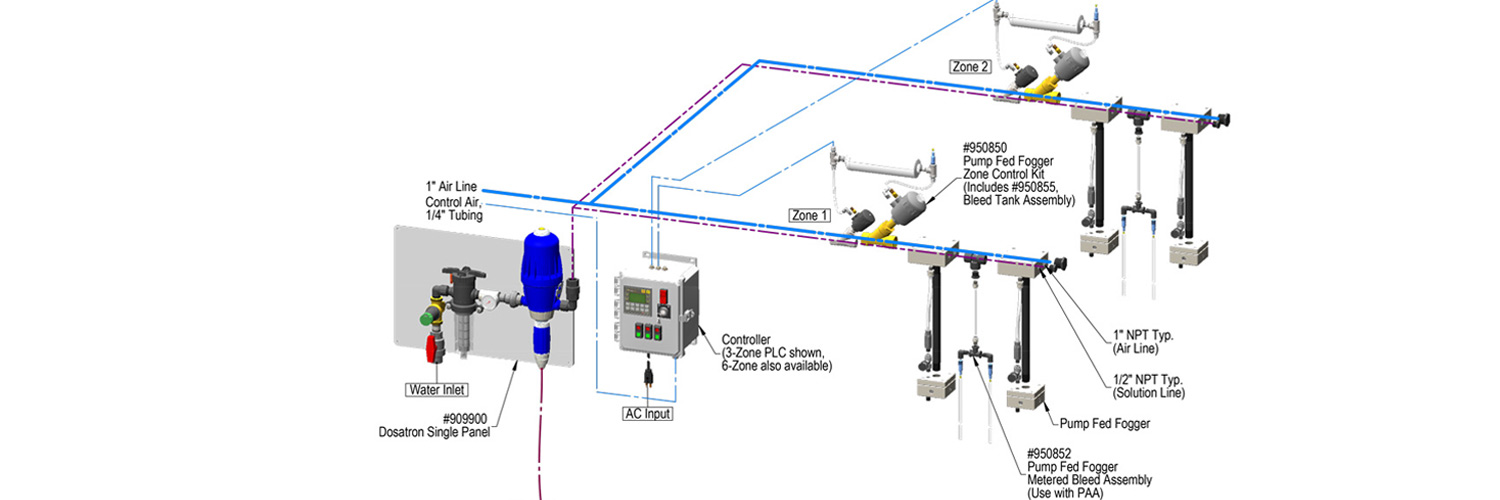

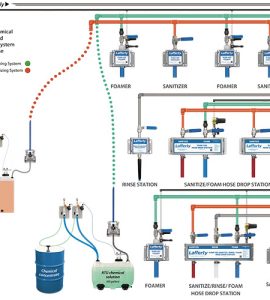

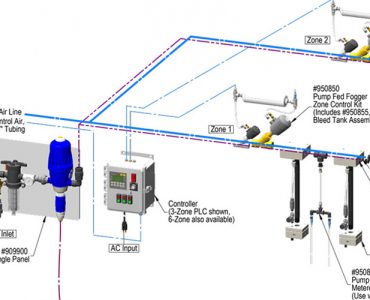

Fogging with Proven Results

Fogging can disinfect surfaces many times faster than hand wiping and is easy to incorporate into any new or established cleaning process. Learn about Lafferty Fogger configurations and how to validate results with ATP...

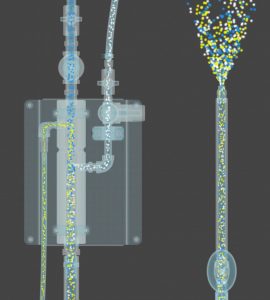

Dilution Procedure for Water-Driven Venturi Systems

This video tutorial demonstrates how to dilute concentrated chemicals to the desired ratio using a Lafferty venturi applicator and metering tips.

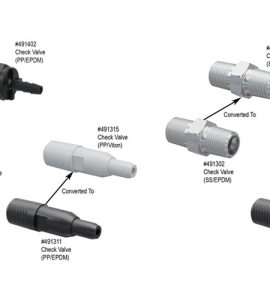

Part Details: Compressed Air Regulator #288350

Lafferty Part #288350 Regulator / Filter, Air, 1/4″ with Weep Used to regulate air pressure in various applications. In many systems, this regulator sets the pump pressure should not be adjusted during the course...

Pump Manual: Flojet G70C (ATEX, Kalrez)

Upgrade for Lafferty Transfer Systems: Kalrez, ATEX Pump# 941600-ATEX The 1-Way FPS Transfer System with ATEX Pump Upgrade features EPDM hoses, Kalrez pump diaphragms, and a grounding wire – making it suitable for...

Operating Instructions for Air-Assisted Venturi Foamers

This video tutorial explains basic operating instructions and best practices for Lafferty air-assisted foamers.