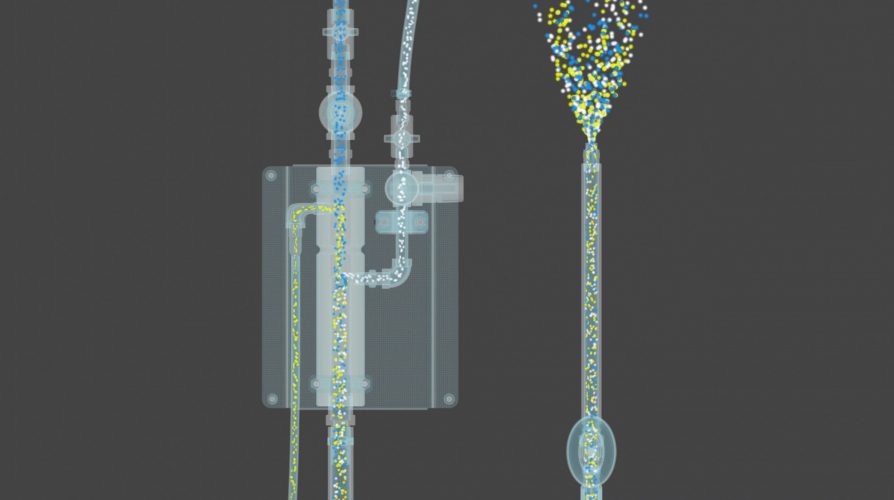

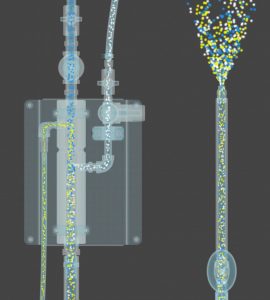

Many Lafferty products use the venturi effect to dilute chemicals by drawing concentrates into the water stream on demand.

Welcome to the Lafferty Learning Center

Discover new products and learn how to select, install, operate, and maintain chemical application equipment. The Lafferty Learning Center presents decades of institutional knowledge, tips/tricks, and best practices in a visual multimedia format.

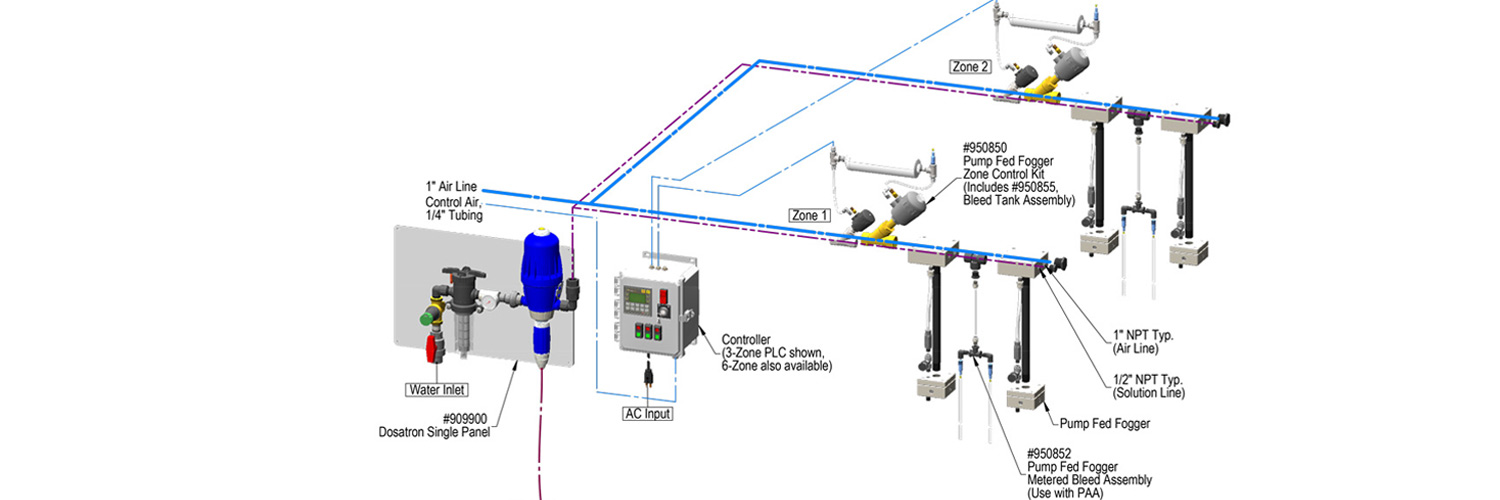

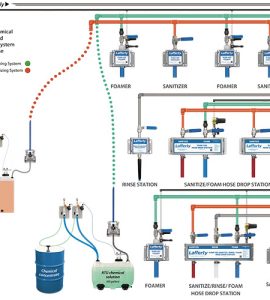

Product specific guidelines are provided in the Installation and Operation Instructions for each unit, which are available on the main Lafferty website.

Post Archive

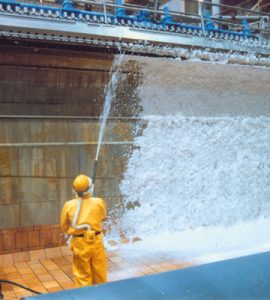

Maintenance Principles for Water-Driven Venturi Systems

This video tutorial reviews simple principles to maintain top performance of Lafferty applicators and dilution systems over time.

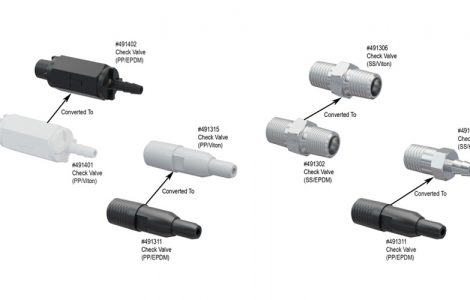

Part Details: Air Check Valves #491302 & 491306

How to disassemble air check valves for inspection and cleaning.

Stainless Steel Foggers

Stainless steel materials of construction may be required for certain pharmaceutical or food/beverage manufacturing facilities. Many fogger models are available with stainless steel fogger bodies and metering tip...