Overview

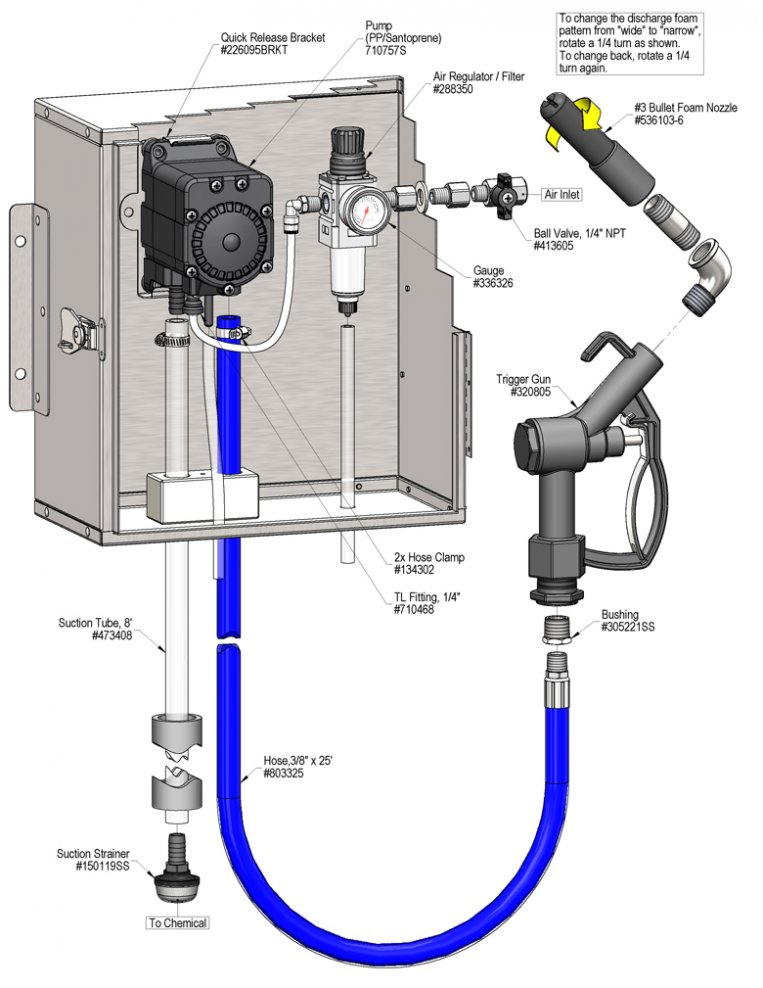

The AF Teat Foam Sprayer is a unique foam applicator for spraying foaming teat dips. This pump-driven system uses compressed air to power an AODD pump to draw and pressurize ready-to-use teat dip. The solution flows through the discharge hose and trigger gun to the "airless" foam nozzle which draws in atmospheric air to project a low volume of wet, clinging foam. The foam pattern width is adjustable.