Overview

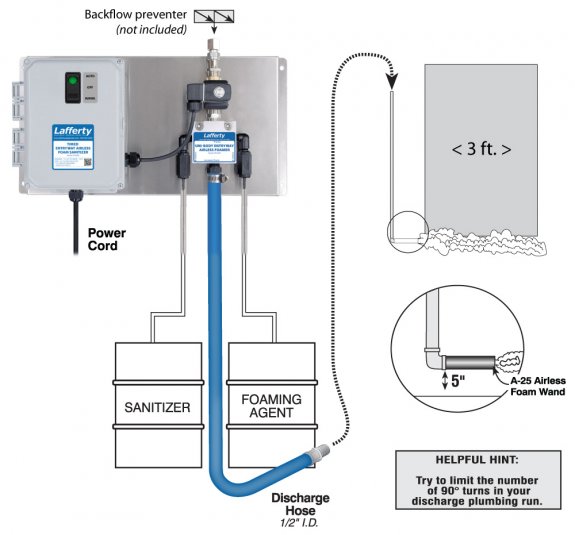

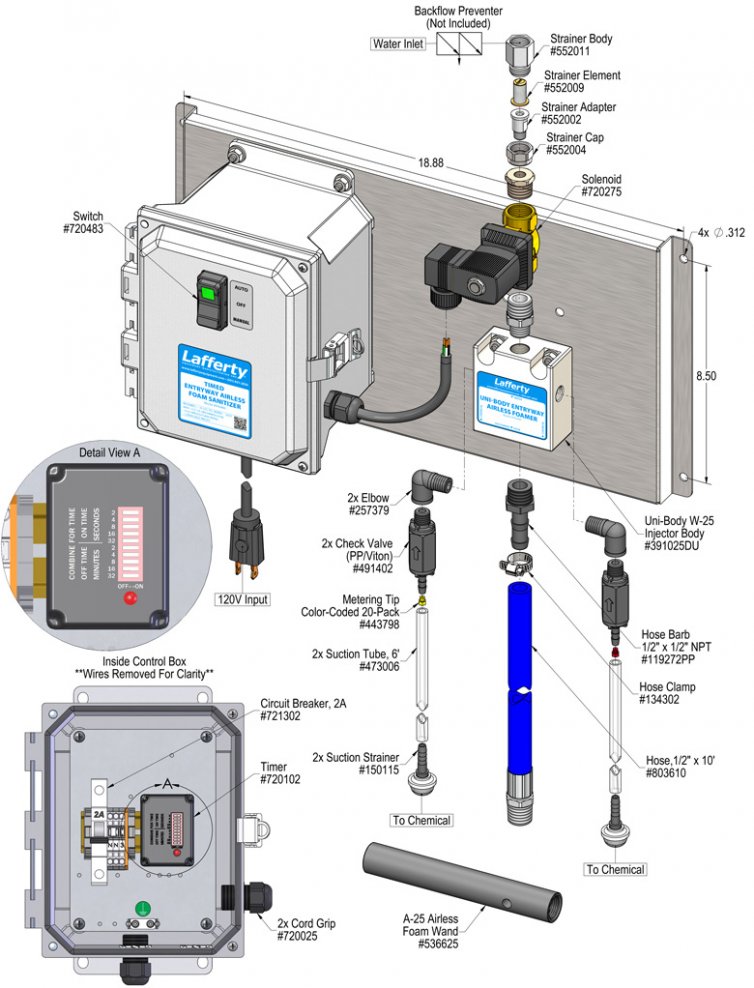

The Timed Entryway Airless Foam Sanitizer is an automated foam applicator for projecting sanitizing chemicals on to floors of 3' wide employee walk doors to prevent cross contamination, without compressed air. When activated, this venturi injection system uses city water pressure (35 - 125 PSI) to draw and blend chemical concentrate into the water stream to create an accurately diluted solution. The solution flows through the discharge hose to the airless foam wand which draws in atmospheric air to create wet, clinging foam. The system timer is user-programmable to meet the needs of any facility.