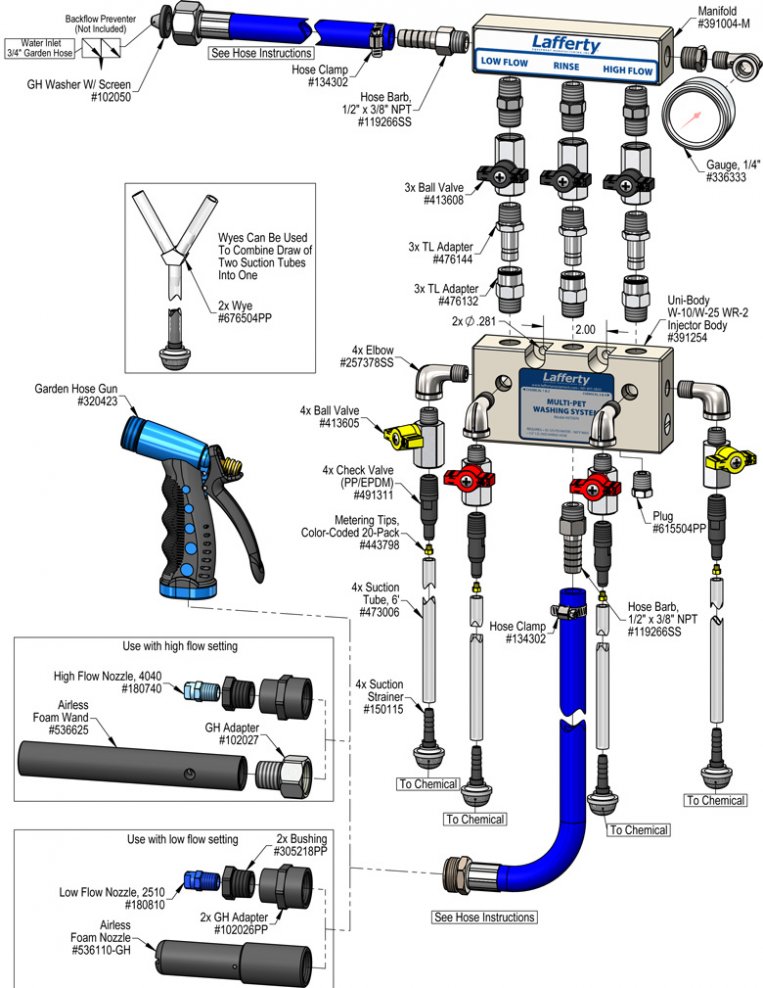

- 2-tubing Wye's are provided to join one low flow and one high flow together into a single tube if only 2 chemicals will be used. (See drawing)

- The left inlet valve is the low volume foam side and works with the low flow airless foam wand.

- The middle inlet valve is for rinsing.

- The right inlet valve is the higher volume foam side and works with the high flow airless foam wand.

Always make sure the discharge hose is in your hand and pointed in a safe direction before turning any of the water inlet valves on. Discharge can be shut off at any time during operation but

should not be left off for long periods of time with water valve on

Open only one water and one chemical ball valve at a time, unless you want a blend of two chemicals.

TO FOAM

- Securely connect the airless foam wand you want to use to the gun.

- Completely open the appropriate inlet ball valve and one chemical valve to begin application. There is no right or wrong way to apply the foam, work out your own method.

- Pull the trigger gun to apply foam.

- Make final metering tip adjustments based on foam quality and cleaning results.

TO RINSE

- A gentle rinsing can be done through either of the airless foam wands.

- For a more powerful rinse exchange the airless foam wand with trigger gun or either of the 2 nozzles.

- The water volume and rinse pressure can also be controlled by partially closing the rinse ball valve.

- If rinsing with the foam wand close the chemical ball valve, open the inlet rinse ball valve.

- If rinsing with the trigger gun quick, remove the foam wand and open the inlet water valve. Squeeze the trigger to begin rinsing. When finished, release the trigger and close the rinse ball valve. Squeeze the trigger to relieve pressure in the hose before trying to remove the gun.

TO SPRAY

- For non-foaming chemicals or for applying chemical with no foam. Connect the dark blue nozzle for the low flow and the light blue nozzle for the high flow to the gun.

- Open the appropriate inlet ball valve and the chemical ball valve.

- Pull the trigger to apply the spray.

CHEMICAL COMPATIBILITY NOTE: The check valves on this unit are

EPDM, which is compatible with a wide range of shampoos, conditioners,

and other detergents. Some oil based or citrus scented products may be

chemically incompatible with EPDM and cause the internal components to

swell and stop drawing chemical. If this occurs, please contact us to

discuss alternate check valve materials.