Overview

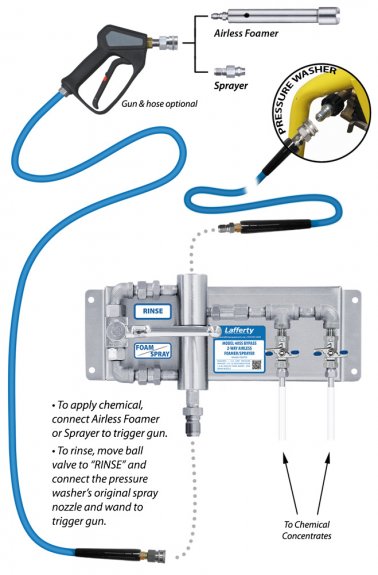

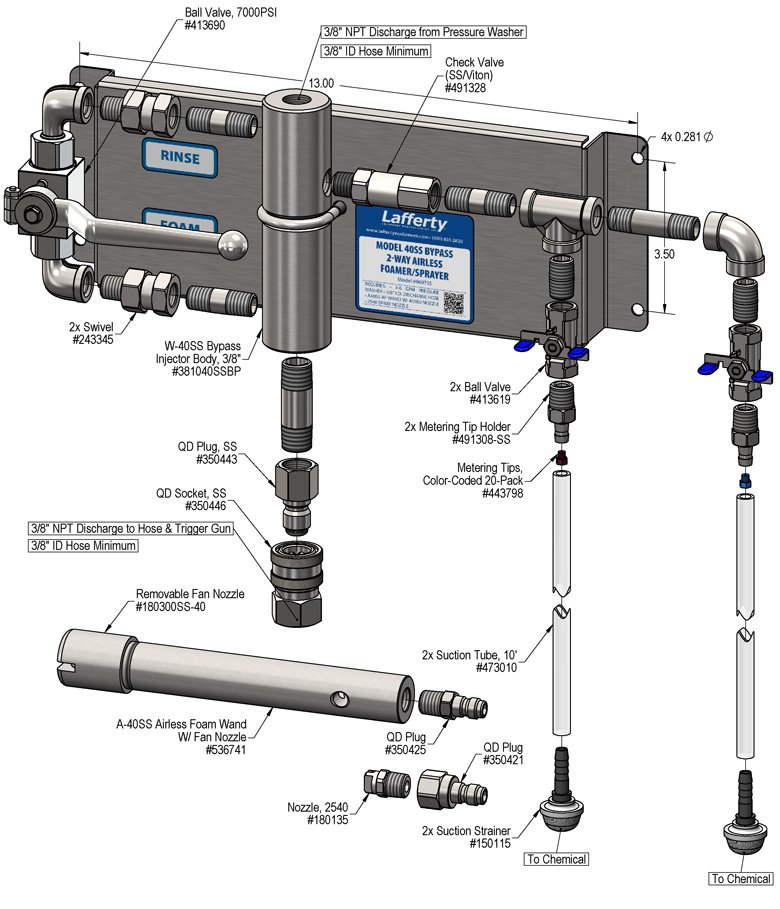

The Model 40 SS Bypass 2-Way Airless Foamer/Sprayer is a wash/rinse system for quickly applying two chemicals and rinsing through the same hose. Using a 5 - 8 GPM pressure washer, this stainless steel venturi injection system draws and blends two separate chemicals or two different concentrations of the same chemical into the water stream to create an accurately diluted solution. The solution is then projected through the discharge hose and foam wand where it draws in atmospheric air to create wet, clinging foam. Use the spray nozzle to apply non-foaming chemicals and simply open the bypass ball valve to rinse at full volume and pressure.