Overview

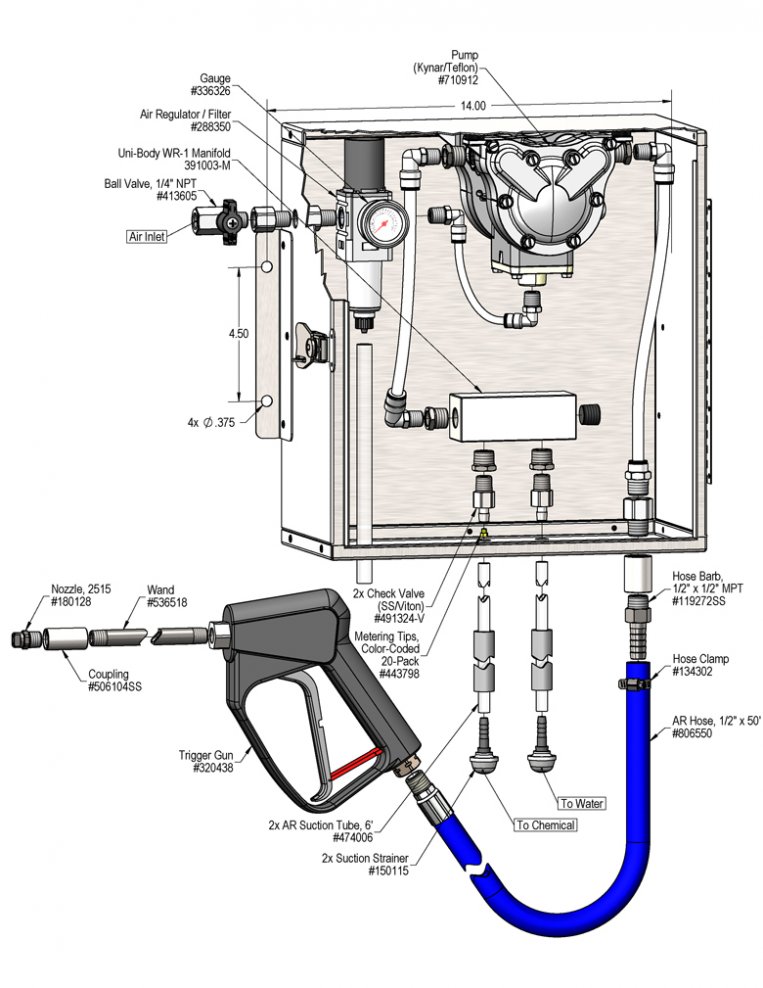

The 1-Way MT-AP Solvent Sprayer is a solvent spray applicator for either applying neat chemical or diluting "on-the-fly". This system is designed for facilities with low or no water pressure. It is suitable for handling many solvents (including d-limonene) and features a lockable, stainless steel enclosure. It uses a 3/8" Warren Rupp air-operated, double-diaphragm pump to draw either ready-to-use chemical from a static tank or a chemical concentrate and water from two tanks and blend them using precision metering tips. The solution is then projected through the discharge hose, trigger gun, wand and fan nozzle.