Overview

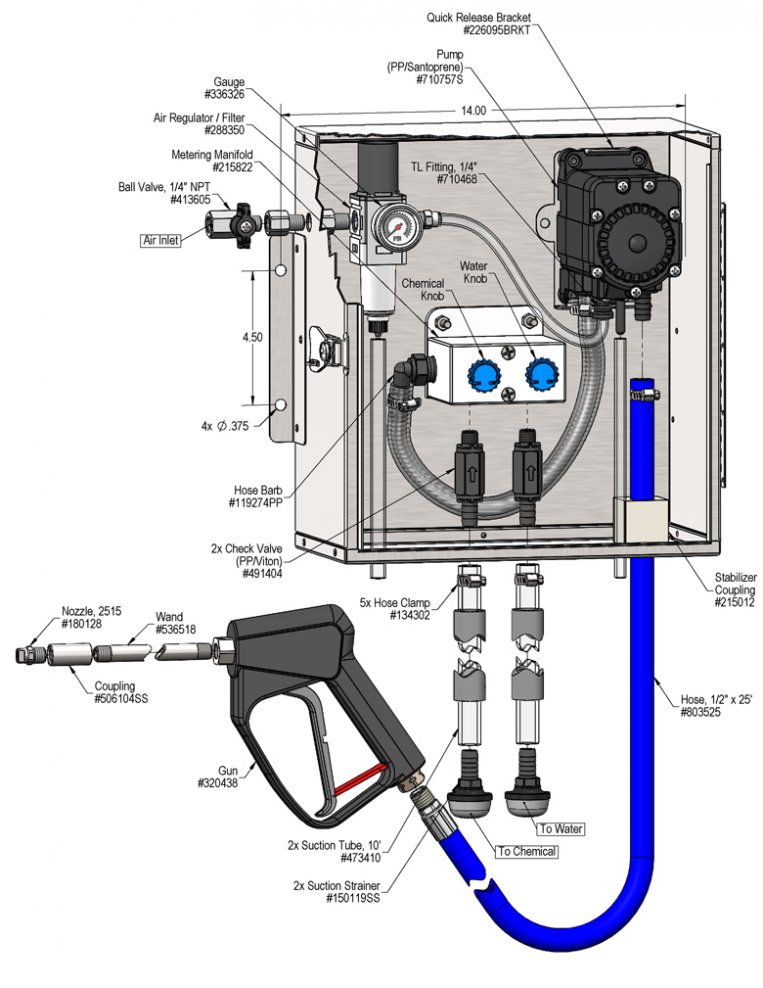

The FPS-MM Asphalt Release Sprayer is a chemical spray applicator for diluting and projecting asphalt release chemicals on to truck beds or tools to prevent asphalt from sticking. This system features a lockable, stainless steel enclosure and uses a cost-effective 1/4" Flojet air-operated, double-diaphragm pump to draw chemical concentrate and water from separate static tanks and blend them to create virtually any dilution ratio (or draw neat chemical). The solution is then projected through the hose, trigger gun, wand and fan nozzle.