Overview

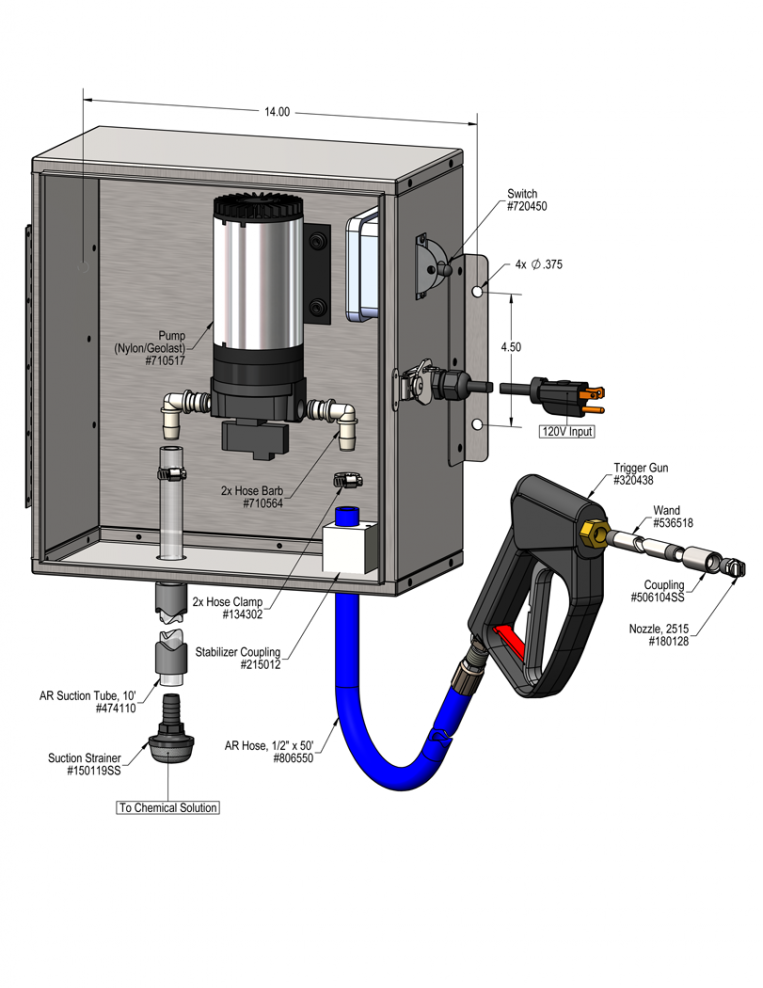

The Electric 1.5 PD Solvent Sprayer is a spray applicator for projecting pre-diluted or neat chemical solutions at 1.5 GPM. An electric pump, with Nylon body and Geolast diaphragms for chemical compatibility, draws solution from a static container and provides the pressure to project the solution as a fan pattern spray on to any surface.