| Water Temperature | up to 180°F |

| Pressure Washer | 2.2 - 5.5 GPM |

| Supply Hose | 3/8" ID minimum |

Lafferty Equipment Manufacturing, LLC

Installation & Operation Instructions

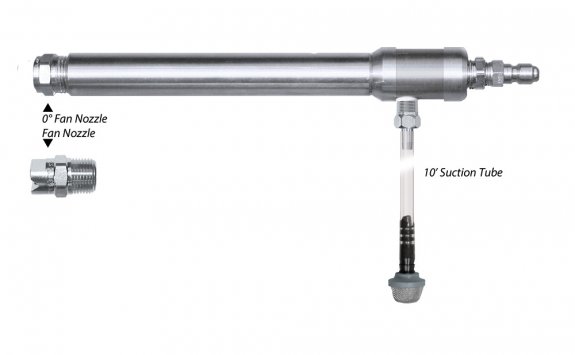

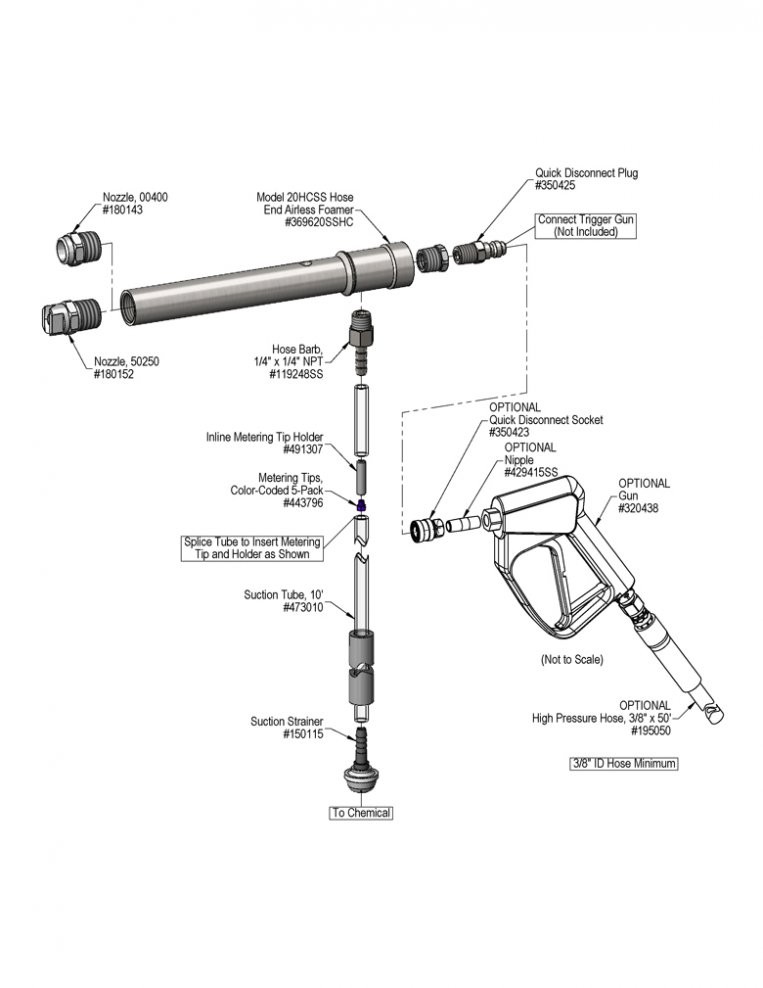

Model # 969620HC · Model 20 SSHC Hose End Airless Foamer

Requirements

Overview

Designed for 2.2–5.5 GPM pressure washers. The Model 20 HC Stainless Steel Hose End Airless Foamer is a "high concentrate" airless foam applicator for quickly diluting and applying foaming chemicals at strong dilution ratios. Weaker dilution ratios are controlled with metering tips. This venturi unit draws and blends a high volume of chemical concentrate into the water stream to create a strong solution. The solution then flows through the airless foam wand which draws in atmospheric air to create and project wet, clinging foam on to surfaces up close or at distances up to 20 feet with interchangeable fan and zero degree nozzles.