Overview

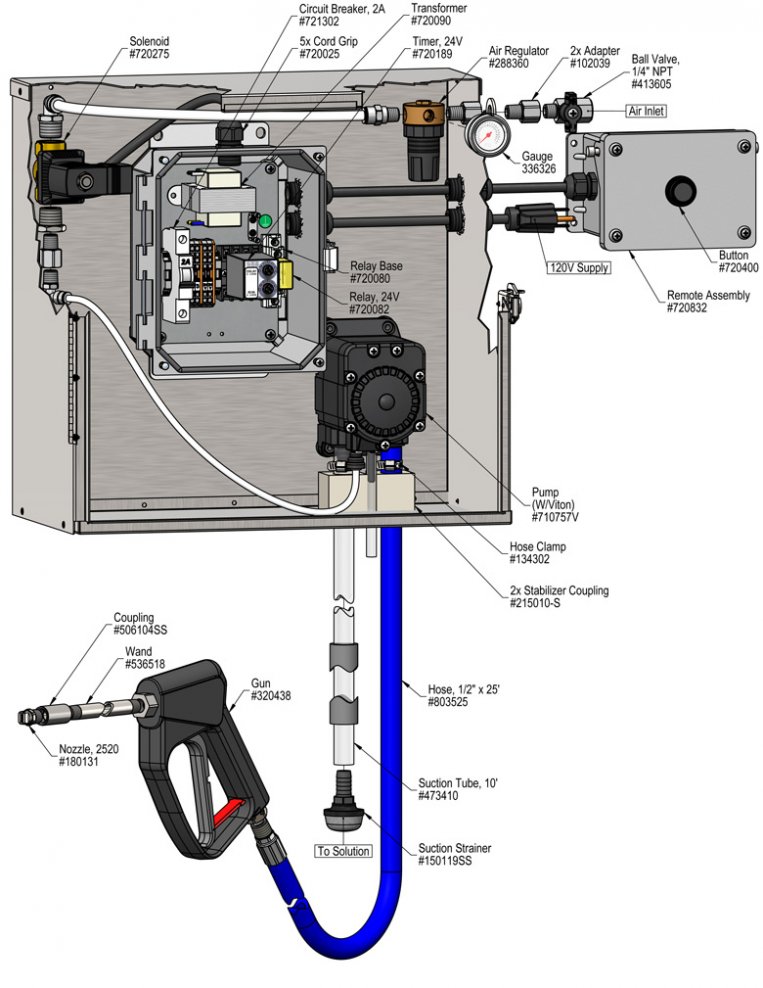

The Timed FPV-PD Asphalt Release Sprayer is a chemical spray applicator for projecting ready-to-use asphalt release chemicals on to truck beds or tools to prevent asphalt from sticking. This unit features an adjustable dual-function 110V timer which controls the length of application and the delay time, which keeps the driver from immediately restarting the system. When the activation button is pressed, a Flojet air-operated, double-diaphragm pump draws pre-diluted chemical solution from a static tank and projects it through the discharge hose, trigger gun, wand and fan nozzle.