| Chemical concentrate or ready to use solution | |

| Compressed Air | up to 4 CFM |

| Electric | 120V |

Lafferty Equipment Manufacturing, LLC

Installation & Operation Instructions

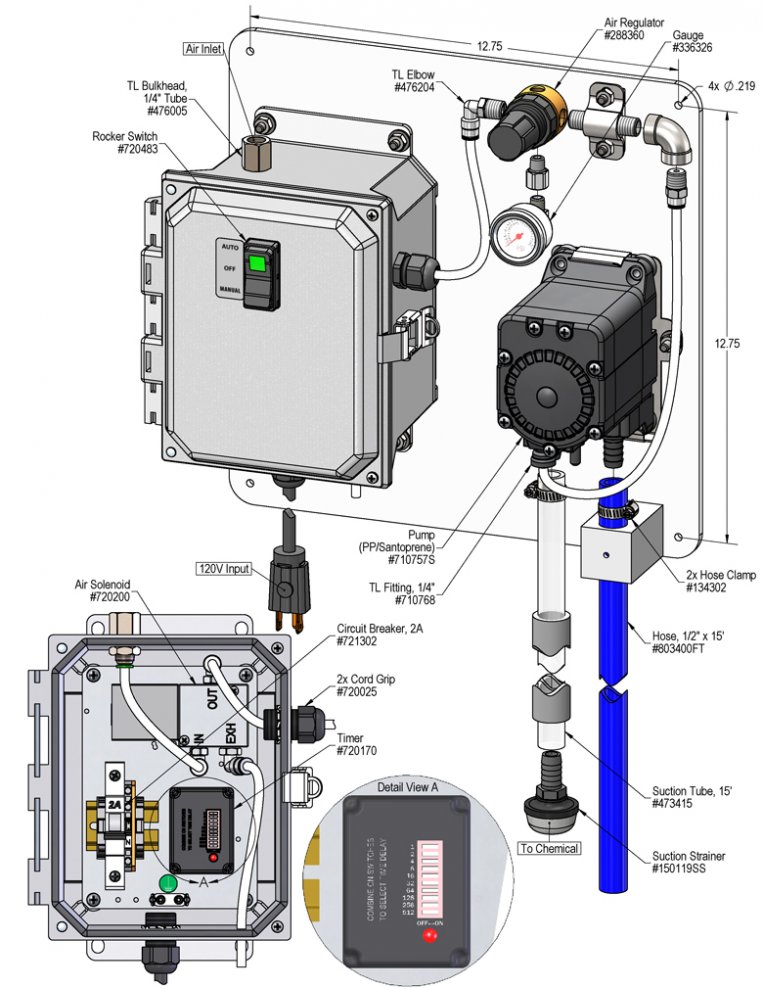

Model # 941621 · Timed FPS Transfer System

Requirements

Overview

The Timed FPS Transfer System is a chemical transfer system for filling any size container with chemical concentrate or ready-to-use solution. Compressed air powers a FloJet air pump which draws chemical from a bulk container and dispenses it into any other container. This unit features on/off rocker switch activation with an adjustable timer to help prevent over usage.