Overview

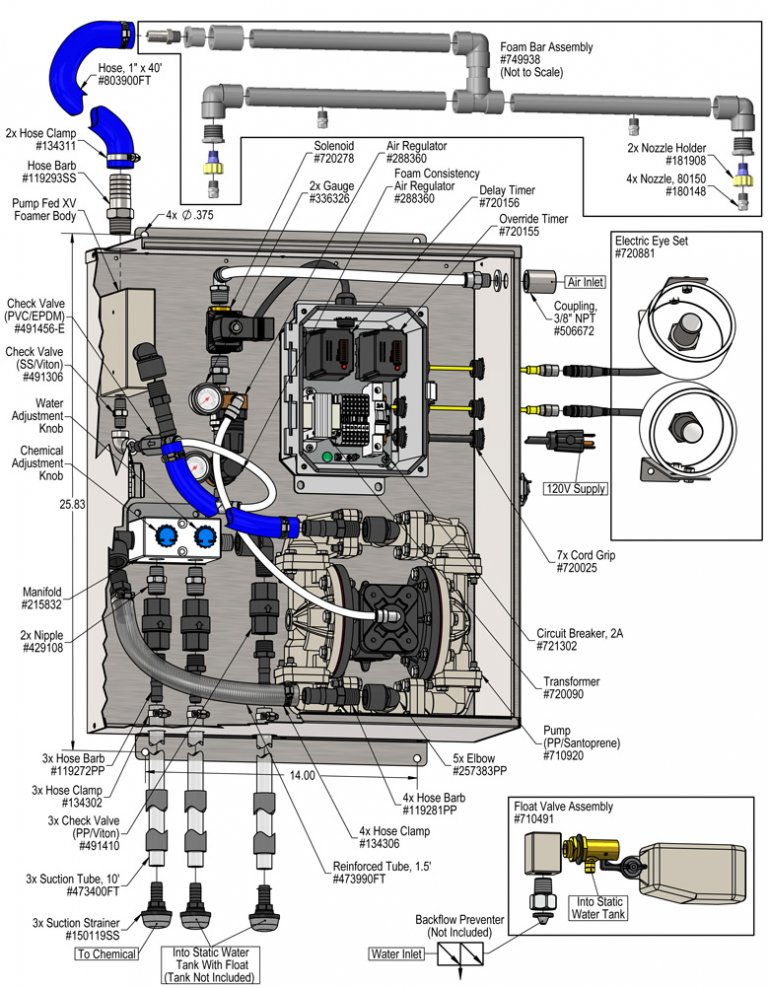

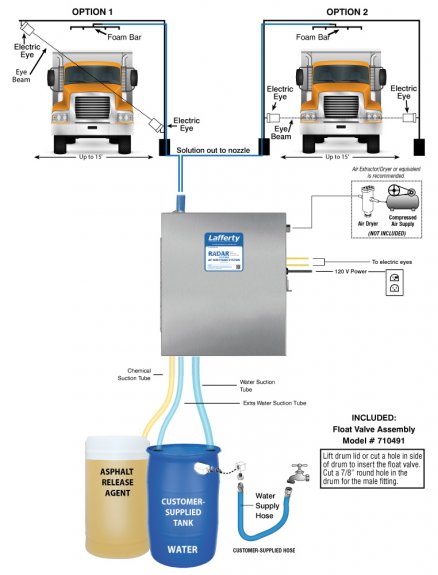

The RADAR™ AP-MM Foam System is an electric eye activated foam applicator that mounts to a user-supplied drive-though arch for applying asphalt release chemicals to truck beds. It is designed for facilities with low or fluctuating water pressure. This system uses compressed air to drive a rugged Sandpiper air-operated, double-diaphragm pump which draws chemical concentrate and water from separate static tanks and blends them "on-the-fly" to create an accurately diluted solution. Rich, clinging foam is created by injecting compressed air into the solution to greatly expand volume and coverage ability. When a truck breaks the electric eye's line-of-sight, a delay timer allows the driver to position the truck under the foam bar before foaming begins and a run timer applies release agent for a pre-set time or until the vehicle leaves the foaming area, whichever is first.

.jpg&sizex=575&sizey=100)